Dairy is an important commodity in the Pacific Northwest, where the climate, land and available

feed draw dairy producers to the region. Dairies supply cooperatives and other processors with

raw milk. Cooperatives and independent processors then bottle milk and make a large array of

dairy products such as cheese, yogurt, butter and powdered milk. These products are then sold

locally, nationally and globally.

Nationally, Idaho ranks fourth in milk production behind California, Wisconsin and New York;

Washington state ranks tenth and Oregon nineteenth. Globally, the U.S. ranks second in milk

production behind the EU.

Northwest Dairy Production

Idaho

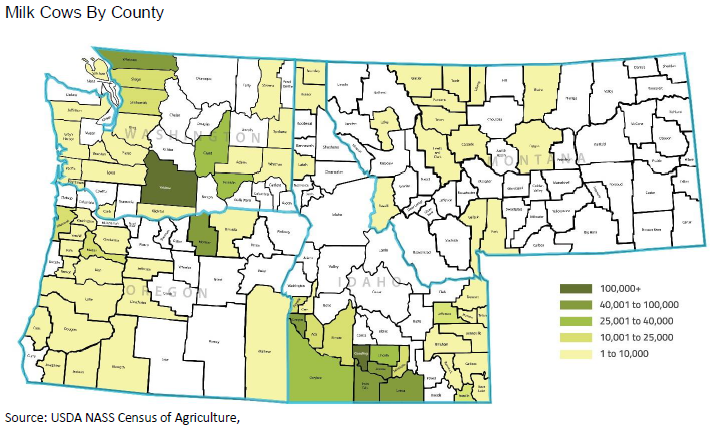

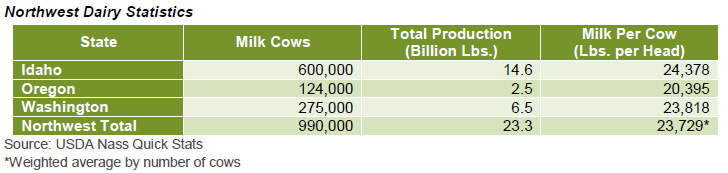

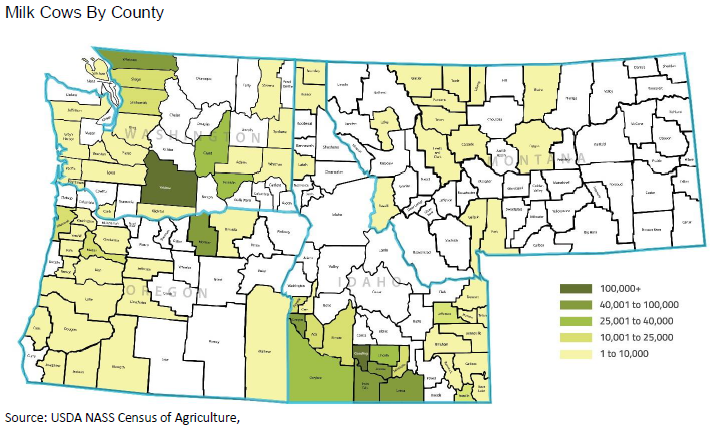

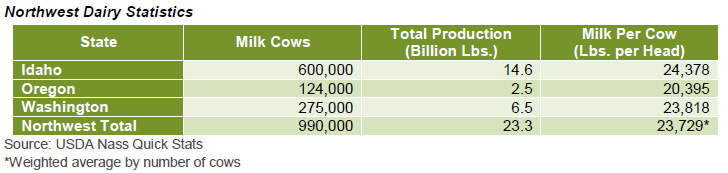

In 2017, cash receipts from dairy products produced on Idaho farms amounted to $2.4 billion. Dairy ranked as the largest single sector in the state's agriculture industry. Idaho is home to around 500 dairy operations, with an estimated 600,000 milk cows. The majority of these cows (70 percent) are located in the Twin Falls area, also known as the Magic Valley. The Treasure Valley, located in the Boise area, is home to more than 15 percent of Idaho's milk-cow herd. The state average annual milk per cow was 24,378 pounds in 2017, compared to 9,793 pounds in 1970.

Idaho dairies produced 14.6 billion pounds of milk in 2017. The majority of Idaho's milk production goes toward cheese manufacturing. Surpassed only by California and Wisconsin, Idaho is the third-largest manufacturer of natural and processed cheese in the U.S., producing more than 959 million pounds of cheese in 2017.

Washington

Dairy products represent the second-largest agriculture sector in Washington, surpassed only by apples. Dairy products accounted for $1.1 billion of receipts in 2017. Washington ranks 10th in the U.S. in terms of total milk production. Washington ranks eighth in the nation in milk cow efficiency, with 23,818 pounds of milk per cow per year. In 2017, total milk production in the state was 6.5 billion pounds. Washington has approximately 465 dairies with an estimated 275,000 dairy cows as of 2017. The largest dairy county, Yakima County, has 38 percent of Washington's cows, and Whatcom County is the second-largest dairy county with 17 percent of the state's milking herd.

Oregon

The dairy industry in Oregon produced 2.5 billion pounds of milk in 2017, ranking 19th in the country in total production of milk products. However, Oregon ranked 31st in per-cow production at 20,395 pounds of milk per cow per year. Morrow County in Northern Oregon contains 33 percent of all milk cows in the state. Other major dairy counties include Tillamook, Marion, Yamhill, Polk and Klamath in descending order by herd size.

Value Chain

The dairy value chain involves production, transport, processing, packaging and marketing. In the Northwest, an independent company or a vertically integrated business can conduct each of these steps. Production Livestock and feed are the main inputs for dairy production. Heifer calves, springers (heifers close to calving) and cows are or will be the milk producers. Bull calves are generally sold as "day-old" calves and raised as beef animals. Because most dairies use artificial insemination (AI) techniques, bulls are kept only to breed cows when artificial insemination is unsuccessful.

Dairies have two options for sourcing cows. They can raise heifer calves born on farm to maturity or they can purchase mature cows or springers. Once a cow or springer freshens (calves and begins producing milk), she can produce milk for approximately 305 days, with peak milk occurring during the first 100 days after calving. Average production is between 55 and 65 pounds per head per day and varies based on region, feed, breed and seasonal weather conditions.

The Magic Valley of Idaho and the Yakima Valley of Washington are two of the largest dairy hubs in the U.S., with adequate feed and water supplies as well as moderate and dry weather conditions making them excellent dairy regions. In the Northwest, production tends to decrease in winter months as cows dedicate more energy to staying warm. Higher-quality feed rations can increase production levels, as can cow breed. Holsteins, for example, produce significantly more milk than Jerseys.

Feed is a key component of milk production. Rations for lactating dairy cows are formulated based on crude protein and net energy for lactation. To achieve maximum production, rations are also balanced for effective fiber, non-structural carbohydrates, ruminal un-degraded protein, soluble protein and other nutritional characteristics of the feed. Alfalfa hay and protein meals (soybean, canola and cottonseed meals) are the major sources of protein. Grain and silage - both corn and haylage - are sources of energy and protein. Adequate levels of minerals are also important. These ingredients are fed to cows as a total mixed ration (TMR). The majority of dairy rations consists of alfalfa hay and corn silage. Pasture-based dairies are still common but tend to be smaller and provide mixed rations during the winter.

Dairies have several sources of income; milk sales account for the largest portion of revenue. The sale of cull cows, heifers and bull calves also contributes to dairy income.

Transport

Milk is collected from dairies in large, insulated tanker trucks. Large dairies ship several trucks per day whereas smaller dairies may ship milk only every two days. Generally, independent trucking companies ship milk from farms to processors. Producers pay for shipping and processors coordinate where milk is sent.

Processing/Packaging/Marketing

Processors range from small independent creameries serving niche markets to cooperatives (co-ops) and privately held processors.

Small creameries may be vertically integrated dairies or have a close marketing relationship with a dairy. These processors bottle milk or make relatively small batches of artisanal dairy products, such as cheese, which are generally marketed to consumers near their facility.

Co-ops process and market a significant amount of milk in the Northwest. These processors source milk from member/owner dairy farmers and use the milk in a wide array of products. Through their product mixes, co-ops may differentiate themselves through two marketing streams. The first is branded consumer products, such as fluid milk, cheese, butter, cottage cheese, cream cheese and ice cream, which are marketed widely to consumers through retail 4 outlets. Products may be packaged under the co-op's brand or co-branded with another company. The second marketing stream is dairy ingredients, primarily milk powder and cheese. Co-ops sell these commodities to food manufacturers who in turn make value-added products.

Private processors purchase milk from co-ops and directly from producers. Processing facilities are generally specialized (a cheese, yogurt or powder plant) as part of a geographically diverse product mix.

Milk Pricing and Marketing Infrastructure

Dairy producers receive varying milk prices depending on the milk components (fat and protein) and the specific contractual agreements established with the bottler or processor. The milk price includes adjustments for component content and quality. The baseline for component content in the industry is 3.5 percent butterfat and 3 percent protein.

Milk quality is essentially a measure of overall herd health and management as expressed by somatic-cell count, which indicates the proportions of bacteria in milk.

Dairies generally receive a price premium when tests of their product confirm butterfat content of 3.5 percent or more. The composition of feed rations can increase butterfat levels, as can cow breed. Jerseys, for example, produce significantly more butterfat than Holsteins. Dairies may also receive premiums for product with somatic-cell counts of 200,000 or less per milliliter.

Most states participate in the Federal Milk Market Order (FMMO), which governs local prices under 11 regional FMMO areas. California, Montana and Southern Idaho do not participate in the FMMO. Washington, most of Oregon and North Idaho do participate in the FMMO.

Milk marketed under the Federal Milk Order is priced in one of four categories:

For example, the blend price paid in Washington and Oregon has been based on a use of 29 percent Class I, 7 percent Class II, 37 percent Class III and 27 percent Class IV milk. The portions fluctuate each month based on use. In broad terms, states that market under the Federal Milk Order receive higher prices than dairies in Idaho or California due to the upward pricing influence of fluid milk. However, the reverse is true when cheese prices are high relative to other milk classes. In Idaho, the milk price is calculated according to cheese yield, or a blend of Class III and Class IV prices, because the milk is generally purchased for the components needed to make cheese.

Industry Drivers Global Markets Eight major dairy commodities are traded in international markets:

New Zealand is the largest exporter of dairy products followed by the EU and the U.S. Australia, Belarus, Argentina, Canada and the Ukraine are minor dairy exporters. Export demand in international markets continues to be a significant driver for the Northwest. Monetary exchange rates can have significant impacts on dairy markets.

Regulation Capital requirements to conform to new rules and regulations are a dairy industry driver. In Washington state, proposed rules concerning nutrient (manure) management may necessitate additional lagoon capacity and a larger land base to spread manure.

Livestock Improved breeding protocols and the use of sexed semen have created an abundance of highquality heifers in replacement programs. While a cull rate of 35 percent or more might have been alarming in the past, it is more typical today as the consistent supply of heifers is allowing operations to maximize efficiencies and still maintain herd size.

Robotics Dairy production is labor intensive and heavily dependent on low-cost labor to support growth. Historically, the U.S. dairy industry has relied on migrant laborers from Mexico and Latin American countries. Challenges with immigration policy in recent years have led to labor shortages and rising labor costs, and have ultimately constrained growth in key dairy-producing areas across the United States.

Robotic milking is a potential solution to the problems of rising labor costs and labor shortages. Robotic milking systems, also called Automatic Milking Systems (AMS), became widely available to dairy producers in the early 1990s and were popular in Europe before gaining popularity in the U.S.

Robotic milking systems have realized greater use by smaller operations, primarily those milking less than 250 cows per day. Due to increasing labor costs and constraints on labor supply, commercial operations with more than 250 milking cows are exploring ways to adopt robotic milking systems.

There are three types of robotic milking systems.

Best Practices

Dairy producers implement various strategies to remain competitive and position their businesses for long-term success. This section details best practices used by Northwest dairy producers.

Strong Operational Management

Successful operators fully understand their production capacity and costs, and have a specific management plan to balance production levels, costs and market returns. Dairy producers implementing the following proven best practices are well positioned for ongoing prosperity and future growth.

Financial Management

Glossary

Alfalfa – A leguminous crop for forage or hay used in livestock feeding

Baler – A piece of machinery that compresses and binds hay/alfalfa into bales to feed cows

Biosecurity – Any of a broad range of practices enforced at a dairy farm to prevent transmittal of pathogens from other sources by feed, cattle, people or other animals

Butter – Made by churning or shaking pasteurized cream until the butterfat separates from the remaining fluid, called buttermilk

Blend price – A minimum weighted average price paid to producers based on the Federal Milk

Orders. The blend price may be adjusted for butterfat content and plant location.

Bovine – A distinct family of ruminant mammals, referring to cattle

Bull – A sexually mature, uncastrated bovine male

Bulk tank – A large, insulated container that is used to store and cool milk quickly to 2⚬ to 4⚬C (35⚬ to 39⚬F)

Bunk – A feed trough or feeding station for cattle

Bunker – A flat rectangular structure used to store forages

Butterfat – The fat that is found in milk; also referred to as milk fat

Calf – A young male or female bovine

Cheese – Made from heating, draining and pressing curds

Cooperative – A firm that is owned by its farmer-members, is operated for their benefit, and distributes earnings based on patronage (volume of milk)

Cow – A mature female bovine that has borne a calf

Cull – To remove a cow from the herd

Curds – The white solid that forms when milk coagulates (clumps together) in the cheesemaking process

CWT (cwt) – Abbreviation for hundredweight, or 100 pounds

Dairy cow – A bovine from which milk production is intended for human consumption

Dairy steer – A neutered male of any of the dairy cattle breeds. "Dairy steers" are raised for meat production and usually managed like beef cattle.

Dam – Mother or female parent in a pedigree

Days-in-milk – The number of days a cow has been milking since the last freshening (calving) 7

Dry cow – A cow that is not lactating or secreting milk after it has completed a lactation period following calving, or a cow that is pregnant and has been taken out of the milking string to allow the cow to prepare itself for freshening

Electronic feeders – Stations in which cows are fed specified amounts of feed by a computer that recognizes their unique electronic identification transponders

Federal Milk Order – A classified pricing system based on Grade A milk use. The four categories are:

Flat barn – An area for milking cattle where the person milking is on the same level as the cow. May be used with a pipeline or bucket milking system. Generally, the same area is used for cow housing.

Fluid milk – Milk that is sold at stores in the form of milk or cream

Forage – Crops high in fiber and grown especially to feed cattle. Includes grasses and legumes cut at the proper stage of maturity and stored to preserve quality

Freshening –When a cow gives birth and begins to produce milk

Fresh cow – A cow that has recently given birth to a calf

Fresh milk – Dairy products having original qualities unimpaired and those recently produced or processed

Grade A or Fluid Grade milk – Milk produced under sanitary conditions qualified for human consumption

Grain – Small, hard, dry seeds, with or without attached hulls or fruit layers, harvested for human or animal consumption. Examples include corn, wheat, soybeans and canola.

Hay – Grass, legumes or other herbaceous plants that have been cut, dried and stored for use as animal feed

Haylage – Hay-silage. A type of moist feed prepared by chopping green alfalfa or grass, kept in airtight silos, and fed to cattle.

Heifer – A young female bovine before she has given birth to a calf and started to produce milk

Holstein – Breed of dairy cow that is black and white in color

Herd – A group of cows; cattle

Homogenization – Process of breaking up fat globules into smaller particles to allow the fat to stay evenly distributed throughout the milk

Hundredweight – Equal to 100 pounds. The symbol for hundredweight is cwt.

Industrial milk – Milk that is sold for further processing into dairy products such as cheese, ice cream, etc.

Jersey – Breed of dairy cow that is usually brown in color

Lactate – To secrete or produce milk

Lactose – A sugar that is found only in milk

Lagoon – Storage pond for manure

Legume – A plant species that has seed pods that split along both sides when ripe. Some of the more common legumes are beans, lentils, peanuts, peas and soybeans.

Mastitis – An inflammation of the mammary gland (or glands), usually caused by bacteria

Raw milk – Milk that has not yet been pasteurized

Manure – Organic matter derived from cattle feces used as an organic fertilizer

Milk powder – Obtained by the partial removal of water from milk

Parlor – The specialized area on the dairy farm where milking is performed. Parlors come in many types: flat barn, walk-through, herringbone, parallel, swing and rotary.

Pasture – Plants, such as grass, grown for feeding or grazing animals

Pasteurization – The process of heating raw milk to a high temperature and cooling it rapidly to kill any natural bacteria that may be present

Pool price or pooling – The price paid by processors for milk based on category of use. Processors pay into or draw out of the pool based on their use of milk relative to market average use. Producers participating in the pool receive identical uniform blend prices, with adjustments for butterfat content and location of the plant to which the milk is delivered.

Processors – Dealers who commonly purchase raw milk then sell pasteurized milk and milk products

Robotic parlor – A completely automated system for milking cows that requires limited human contact

Separator – A centrifuge device used to remove the fat from milk. Formerly used on the farm, but now used primarily at processing plants.

Service – A term that is used to describe the event of artificial insemination

Short-bred heifer – A heifer that is confirmed pregnant and has been pregnant for 0-6 months

Silage – A type of moist feed prepared by chopping green forage, kept in airtight silos and fed to cattle

Silo – A storage facility for silage

Sire – Father or male parent in a pedigree

Skim milk powder – Obtained by removing water from pasteurized skim milk. Contains 5 percent moisture, 1.5 percent butterfat and a minimum milk protein content of 34 percent.

Somatic-cell count – The number of white blood cells (leukocytes) per milliliter of milk. A high concentration of somatic cells indicates possible mastitis infection.

Springer – A heifer that is within 2-3 months of calving

Stall – A cow-housing cubicle

Teat – The appendage on the udder through which milk from the udder flows

Total mixed ration (TMR) – The strategy of feeding complete mixed ration, which includes forages and concentrates

Throughput – The number of cows that can be milked in a parlor in a given period

Udder – The mammary gland of cows where milk is produced

Whey – Watery liquid that is left over when milk forms curds

Whole milk powder – Obtained by removing water from pasteurized, homogenized whole milk. Contains 26-40 percent butterfat, no more than 5 percent moisture and typically less than 27 percent protein.

Northwest Dairy Production

Idaho

In 2017, cash receipts from dairy products produced on Idaho farms amounted to $2.4 billion. Dairy ranked as the largest single sector in the state's agriculture industry. Idaho is home to around 500 dairy operations, with an estimated 600,000 milk cows. The majority of these cows (70 percent) are located in the Twin Falls area, also known as the Magic Valley. The Treasure Valley, located in the Boise area, is home to more than 15 percent of Idaho's milk-cow herd. The state average annual milk per cow was 24,378 pounds in 2017, compared to 9,793 pounds in 1970.

Idaho dairies produced 14.6 billion pounds of milk in 2017. The majority of Idaho's milk production goes toward cheese manufacturing. Surpassed only by California and Wisconsin, Idaho is the third-largest manufacturer of natural and processed cheese in the U.S., producing more than 959 million pounds of cheese in 2017.

Washington

Dairy products represent the second-largest agriculture sector in Washington, surpassed only by apples. Dairy products accounted for $1.1 billion of receipts in 2017. Washington ranks 10th in the U.S. in terms of total milk production. Washington ranks eighth in the nation in milk cow efficiency, with 23,818 pounds of milk per cow per year. In 2017, total milk production in the state was 6.5 billion pounds. Washington has approximately 465 dairies with an estimated 275,000 dairy cows as of 2017. The largest dairy county, Yakima County, has 38 percent of Washington's cows, and Whatcom County is the second-largest dairy county with 17 percent of the state's milking herd.

Oregon

The dairy industry in Oregon produced 2.5 billion pounds of milk in 2017, ranking 19th in the country in total production of milk products. However, Oregon ranked 31st in per-cow production at 20,395 pounds of milk per cow per year. Morrow County in Northern Oregon contains 33 percent of all milk cows in the state. Other major dairy counties include Tillamook, Marion, Yamhill, Polk and Klamath in descending order by herd size.

Value Chain

The dairy value chain involves production, transport, processing, packaging and marketing. In the Northwest, an independent company or a vertically integrated business can conduct each of these steps. Production Livestock and feed are the main inputs for dairy production. Heifer calves, springers (heifers close to calving) and cows are or will be the milk producers. Bull calves are generally sold as "day-old" calves and raised as beef animals. Because most dairies use artificial insemination (AI) techniques, bulls are kept only to breed cows when artificial insemination is unsuccessful.

Dairies have two options for sourcing cows. They can raise heifer calves born on farm to maturity or they can purchase mature cows or springers. Once a cow or springer freshens (calves and begins producing milk), she can produce milk for approximately 305 days, with peak milk occurring during the first 100 days after calving. Average production is between 55 and 65 pounds per head per day and varies based on region, feed, breed and seasonal weather conditions.

The Magic Valley of Idaho and the Yakima Valley of Washington are two of the largest dairy hubs in the U.S., with adequate feed and water supplies as well as moderate and dry weather conditions making them excellent dairy regions. In the Northwest, production tends to decrease in winter months as cows dedicate more energy to staying warm. Higher-quality feed rations can increase production levels, as can cow breed. Holsteins, for example, produce significantly more milk than Jerseys.

Feed is a key component of milk production. Rations for lactating dairy cows are formulated based on crude protein and net energy for lactation. To achieve maximum production, rations are also balanced for effective fiber, non-structural carbohydrates, ruminal un-degraded protein, soluble protein and other nutritional characteristics of the feed. Alfalfa hay and protein meals (soybean, canola and cottonseed meals) are the major sources of protein. Grain and silage - both corn and haylage - are sources of energy and protein. Adequate levels of minerals are also important. These ingredients are fed to cows as a total mixed ration (TMR). The majority of dairy rations consists of alfalfa hay and corn silage. Pasture-based dairies are still common but tend to be smaller and provide mixed rations during the winter.

Dairies have several sources of income; milk sales account for the largest portion of revenue. The sale of cull cows, heifers and bull calves also contributes to dairy income.

Transport

Milk is collected from dairies in large, insulated tanker trucks. Large dairies ship several trucks per day whereas smaller dairies may ship milk only every two days. Generally, independent trucking companies ship milk from farms to processors. Producers pay for shipping and processors coordinate where milk is sent.

Processing/Packaging/Marketing

Processors range from small independent creameries serving niche markets to cooperatives (co-ops) and privately held processors.

Small creameries may be vertically integrated dairies or have a close marketing relationship with a dairy. These processors bottle milk or make relatively small batches of artisanal dairy products, such as cheese, which are generally marketed to consumers near their facility.

Co-ops process and market a significant amount of milk in the Northwest. These processors source milk from member/owner dairy farmers and use the milk in a wide array of products. Through their product mixes, co-ops may differentiate themselves through two marketing streams. The first is branded consumer products, such as fluid milk, cheese, butter, cottage cheese, cream cheese and ice cream, which are marketed widely to consumers through retail 4 outlets. Products may be packaged under the co-op's brand or co-branded with another company. The second marketing stream is dairy ingredients, primarily milk powder and cheese. Co-ops sell these commodities to food manufacturers who in turn make value-added products.

Private processors purchase milk from co-ops and directly from producers. Processing facilities are generally specialized (a cheese, yogurt or powder plant) as part of a geographically diverse product mix.

Milk Pricing and Marketing Infrastructure

Dairy producers receive varying milk prices depending on the milk components (fat and protein) and the specific contractual agreements established with the bottler or processor. The milk price includes adjustments for component content and quality. The baseline for component content in the industry is 3.5 percent butterfat and 3 percent protein.

Milk quality is essentially a measure of overall herd health and management as expressed by somatic-cell count, which indicates the proportions of bacteria in milk.

Dairies generally receive a price premium when tests of their product confirm butterfat content of 3.5 percent or more. The composition of feed rations can increase butterfat levels, as can cow breed. Jerseys, for example, produce significantly more butterfat than Holsteins. Dairies may also receive premiums for product with somatic-cell counts of 200,000 or less per milliliter.

Most states participate in the Federal Milk Market Order (FMMO), which governs local prices under 11 regional FMMO areas. California, Montana and Southern Idaho do not participate in the FMMO. Washington, most of Oregon and North Idaho do participate in the FMMO.

Milk marketed under the Federal Milk Order is priced in one of four categories:

- Class I: fluid milk for consumption (pints, gallons, chocolate milk, etc.)

- Class II: soft products (ice cream, yogurt, cottage cheese, etc.)

- Class III: cheese (American and all others)

- Class IV: butter and powdered milk

For example, the blend price paid in Washington and Oregon has been based on a use of 29 percent Class I, 7 percent Class II, 37 percent Class III and 27 percent Class IV milk. The portions fluctuate each month based on use. In broad terms, states that market under the Federal Milk Order receive higher prices than dairies in Idaho or California due to the upward pricing influence of fluid milk. However, the reverse is true when cheese prices are high relative to other milk classes. In Idaho, the milk price is calculated according to cheese yield, or a blend of Class III and Class IV prices, because the milk is generally purchased for the components needed to make cheese.

Industry Drivers Global Markets Eight major dairy commodities are traded in international markets:

- Whole milk powder (WMP)

- Whey powder

- Cheese

- Skim milk powder (nonfat dry milk, or SMP)

- Butter

- Lactose

- Casein

- Condensed milk

New Zealand is the largest exporter of dairy products followed by the EU and the U.S. Australia, Belarus, Argentina, Canada and the Ukraine are minor dairy exporters. Export demand in international markets continues to be a significant driver for the Northwest. Monetary exchange rates can have significant impacts on dairy markets.

Regulation Capital requirements to conform to new rules and regulations are a dairy industry driver. In Washington state, proposed rules concerning nutrient (manure) management may necessitate additional lagoon capacity and a larger land base to spread manure.

Livestock Improved breeding protocols and the use of sexed semen have created an abundance of highquality heifers in replacement programs. While a cull rate of 35 percent or more might have been alarming in the past, it is more typical today as the consistent supply of heifers is allowing operations to maximize efficiencies and still maintain herd size.

Robotics Dairy production is labor intensive and heavily dependent on low-cost labor to support growth. Historically, the U.S. dairy industry has relied on migrant laborers from Mexico and Latin American countries. Challenges with immigration policy in recent years have led to labor shortages and rising labor costs, and have ultimately constrained growth in key dairy-producing areas across the United States.

Robotic milking is a potential solution to the problems of rising labor costs and labor shortages. Robotic milking systems, also called Automatic Milking Systems (AMS), became widely available to dairy producers in the early 1990s and were popular in Europe before gaining popularity in the U.S.

Robotic milking systems have realized greater use by smaller operations, primarily those milking less than 250 cows per day. Due to increasing labor costs and constraints on labor supply, commercial operations with more than 250 milking cows are exploring ways to adopt robotic milking systems.

There are three types of robotic milking systems.

- Single-stall unit: uses one robotic arm for each stall, the most common system

- Multiple-stall unit: uses one robotic arm for two or more milking stalls

- Automatic Milking Rotary (AMR): uses a rotating platform that may vary in size and employs multiple robotic arms, depending on the size of the platform. Each robotic arm on an AMR may have a specialized function compared to the stall units, where a single robotic arm handles multiple functions.

Best Practices

Dairy producers implement various strategies to remain competitive and position their businesses for long-term success. This section details best practices used by Northwest dairy producers.

Strong Operational Management

Successful operators fully understand their production capacity and costs, and have a specific management plan to balance production levels, costs and market returns. Dairy producers implementing the following proven best practices are well positioned for ongoing prosperity and future growth.

Financial Management

- Establish a liquidity reserve in the form of cash or equities in cows and feed (i.e., borrowing base margin). This margin should be maintained at a target level of $600 per dairy cow equivalent or more. These liquidity reserves will enable an operation to survive through sustained periods of volatility.

- Maintain the integrity of the top half of the balance sheet. Do not use cash reserves for long-term purchases or capital improvements and closely monitor working capital.

- Monitor borrowing base margin changes from period to period. This can be a good preliminary indication of an earnings trend line.

- Reduce leverage, which is a key to long-term survivability. On a market-based balance sheet, leverage under 50 percent should be maintained, while less than 40 percent is preferred.

- Consider the impact of every potential expansion on management, leverage and cash reserves.

- Prepare budgets and be accountable to those budgets. The operation’s management team should convene regularly to review performance. Producers need to be aware of operational performance on a month-to-month basis.

- Have a good understanding of break-evens and use data to make decisions. Though shalt know your costs.

- Evaluate cash flow and look for ways to continually lower capital needs.

- Develop a comprehensive permanent commodity price risk management plan. With continued volatility in both milk price and input costs, producers need to take advantage of all available tools to lock in profitable margins and protect their operation from undue risk.

- Understand and assess counterparty risk. Know your customers and input suppliers.

- Frequent calls with a producers CPA, commodity risk hedging firm, and lender can provide valuable current market data.

- Maintain herd replacement programs with a cow-to-heifer ratio ranging from 1:1 to 1:0.8 if a cost-benefit analysis supports the raise-on-farm versus purchase decision.

- Understand the costs and benefits of a full heifer program relative to purchasing replacements.

- Analyze every aspect of the business to identify areas that can be cut to control expenses, or modified to improve operating efficiency. Examples include evaluation of the heifer program, capital spending (necessity or want), labor strategies, barn efficiency, merits of milking twice vs. three times per day, etc.

- Establish a land base adequate to dispose of all waste. Allocating seven cows per acre is typical. (Even fewer cows per acre are permitted in Oregon and Western Washington.) Consider alternatives to land application such as manure digesters.

- Understand regulations and permitting processes to avoid legal liability that could jeopardize the viability of operations.

- Manage feed costs by contracting feed with custom growers, hedging or controlling a captive feedbase on long-term leased or purchased ground. As feed is typically the largest single expense to a dairy operation, management of this cost is critical.

- Examine feed rations relative to feed component costs to assure the feed ration is as economical as possible for the level of desired milk production and herd health.

Glossary

Alfalfa – A leguminous crop for forage or hay used in livestock feeding

Baler – A piece of machinery that compresses and binds hay/alfalfa into bales to feed cows

Biosecurity – Any of a broad range of practices enforced at a dairy farm to prevent transmittal of pathogens from other sources by feed, cattle, people or other animals

Butter – Made by churning or shaking pasteurized cream until the butterfat separates from the remaining fluid, called buttermilk

Blend price – A minimum weighted average price paid to producers based on the Federal Milk

Orders. The blend price may be adjusted for butterfat content and plant location.

Bovine – A distinct family of ruminant mammals, referring to cattle

Bull – A sexually mature, uncastrated bovine male

Bulk tank – A large, insulated container that is used to store and cool milk quickly to 2⚬ to 4⚬C (35⚬ to 39⚬F)

Bunk – A feed trough or feeding station for cattle

Bunker – A flat rectangular structure used to store forages

Butterfat – The fat that is found in milk; also referred to as milk fat

Calf – A young male or female bovine

Cheese – Made from heating, draining and pressing curds

Cooperative – A firm that is owned by its farmer-members, is operated for their benefit, and distributes earnings based on patronage (volume of milk)

Cow – A mature female bovine that has borne a calf

Cull – To remove a cow from the herd

Curds – The white solid that forms when milk coagulates (clumps together) in the cheesemaking process

CWT (cwt) – Abbreviation for hundredweight, or 100 pounds

Dairy cow – A bovine from which milk production is intended for human consumption

Dairy steer – A neutered male of any of the dairy cattle breeds. "Dairy steers" are raised for meat production and usually managed like beef cattle.

Dam – Mother or female parent in a pedigree

Days-in-milk – The number of days a cow has been milking since the last freshening (calving) 7

Dry cow – A cow that is not lactating or secreting milk after it has completed a lactation period following calving, or a cow that is pregnant and has been taken out of the milking string to allow the cow to prepare itself for freshening

Electronic feeders – Stations in which cows are fed specified amounts of feed by a computer that recognizes their unique electronic identification transponders

Federal Milk Order – A classified pricing system based on Grade A milk use. The four categories are:

- Class I: fluid milk for consumption

- Class II: soft products (ice cream, yogurt, cottage cheese, etc.)

- Class III: cheese

- Class IV: butter or powdered milk

Flat barn – An area for milking cattle where the person milking is on the same level as the cow. May be used with a pipeline or bucket milking system. Generally, the same area is used for cow housing.

Fluid milk – Milk that is sold at stores in the form of milk or cream

Forage – Crops high in fiber and grown especially to feed cattle. Includes grasses and legumes cut at the proper stage of maturity and stored to preserve quality

Freshening –When a cow gives birth and begins to produce milk

Fresh cow – A cow that has recently given birth to a calf

Fresh milk – Dairy products having original qualities unimpaired and those recently produced or processed

Grade A or Fluid Grade milk – Milk produced under sanitary conditions qualified for human consumption

Grain – Small, hard, dry seeds, with or without attached hulls or fruit layers, harvested for human or animal consumption. Examples include corn, wheat, soybeans and canola.

Hay – Grass, legumes or other herbaceous plants that have been cut, dried and stored for use as animal feed

Haylage – Hay-silage. A type of moist feed prepared by chopping green alfalfa or grass, kept in airtight silos, and fed to cattle.

Heifer – A young female bovine before she has given birth to a calf and started to produce milk

Holstein – Breed of dairy cow that is black and white in color

Herd – A group of cows; cattle

Homogenization – Process of breaking up fat globules into smaller particles to allow the fat to stay evenly distributed throughout the milk

Hundredweight – Equal to 100 pounds. The symbol for hundredweight is cwt.

Industrial milk – Milk that is sold for further processing into dairy products such as cheese, ice cream, etc.

Jersey – Breed of dairy cow that is usually brown in color

Lactate – To secrete or produce milk

Lactose – A sugar that is found only in milk

Lagoon – Storage pond for manure

Legume – A plant species that has seed pods that split along both sides when ripe. Some of the more common legumes are beans, lentils, peanuts, peas and soybeans.

Mastitis – An inflammation of the mammary gland (or glands), usually caused by bacteria

Raw milk – Milk that has not yet been pasteurized

Manure – Organic matter derived from cattle feces used as an organic fertilizer

Milk powder – Obtained by the partial removal of water from milk

Parlor – The specialized area on the dairy farm where milking is performed. Parlors come in many types: flat barn, walk-through, herringbone, parallel, swing and rotary.

Pasture – Plants, such as grass, grown for feeding or grazing animals

Pasteurization – The process of heating raw milk to a high temperature and cooling it rapidly to kill any natural bacteria that may be present

Pool price or pooling – The price paid by processors for milk based on category of use. Processors pay into or draw out of the pool based on their use of milk relative to market average use. Producers participating in the pool receive identical uniform blend prices, with adjustments for butterfat content and location of the plant to which the milk is delivered.

Processors – Dealers who commonly purchase raw milk then sell pasteurized milk and milk products

Robotic parlor – A completely automated system for milking cows that requires limited human contact

Separator – A centrifuge device used to remove the fat from milk. Formerly used on the farm, but now used primarily at processing plants.

Service – A term that is used to describe the event of artificial insemination

Short-bred heifer – A heifer that is confirmed pregnant and has been pregnant for 0-6 months

Silage – A type of moist feed prepared by chopping green forage, kept in airtight silos and fed to cattle

Silo – A storage facility for silage

Sire – Father or male parent in a pedigree

Skim milk powder – Obtained by removing water from pasteurized skim milk. Contains 5 percent moisture, 1.5 percent butterfat and a minimum milk protein content of 34 percent.

Somatic-cell count – The number of white blood cells (leukocytes) per milliliter of milk. A high concentration of somatic cells indicates possible mastitis infection.

Springer – A heifer that is within 2-3 months of calving

Stall – A cow-housing cubicle

Teat – The appendage on the udder through which milk from the udder flows

Total mixed ration (TMR) – The strategy of feeding complete mixed ration, which includes forages and concentrates

Throughput – The number of cows that can be milked in a parlor in a given period

Udder – The mammary gland of cows where milk is produced

Whey – Watery liquid that is left over when milk forms curds

Whole milk powder – Obtained by removing water from pasteurized, homogenized whole milk. Contains 26-40 percent butterfat, no more than 5 percent moisture and typically less than 27 percent protein.

Stay up to date

Receive email notifications about Northwest and global and agricultural and economic perspectives, trends, programs, events, webinars and articles.

Subscribe