Introduction

Pacific Northwest Timberland Ownership and Log Production

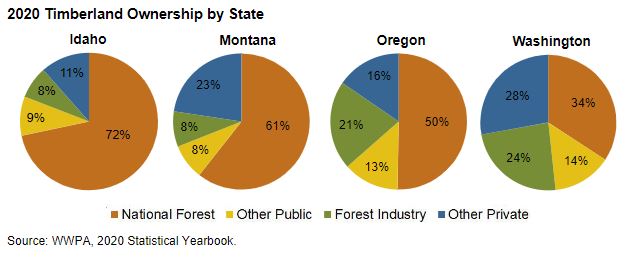

Much of the timberland in the Northwest is publicly held, with approximately two-thirds owned by the U.S. government. Strict environmental restrictions on federal lands have reduced timber harvest from lands managed by the U.S. Forest Service and Bureau of Land Management since the listing of the spotted owl as a threatened species in 1990. Harvest from other public lands (primarily state-held lands) has held relatively steady during that time.

Total timberland production on federal lands has declined over the past 20 years; however, forest products companies have replaced some of this lost timber harvest. Many in the industry believe this has caused overgrowth and resulted in pest and disease problems, as well as increased fire risk. However, due to severe fires the last several summers, more harvesting on federal and state timberland is occurring. While former President Trump issued an executive order in December 2018 to increase forest management across the U.S., total cut amounts on Forest Service lands have remained constant at just over2 billion board feet. The Bureau of Land Management has seen an increase to 256 million board feet from approximately180 in 2018.

The size of private timberland ownership varies from small woodland owners to large, publicly traded companies and industrial landowners. Some timberland owners in the Northwest own upward of 1 million acres. The 80/20 rule applies to ownership; 20%–or less –of owners possess 80%of private timberland.

Over the past two decades, capital demands from forest products manufacturers have increasingly competed with demands from timberland owners. Historically, most companies used an integrated business model, growing and processing their own timber. Conflicting demand on capital and tax advantages afforded to special timberland ownership structures has caused many formerly integrated companies to focus their operations on either growing or processing forest resources and not both.

As a result, a significant portion of Northwest forestland has transferred from vertically integrated corporations to Timber Investment Management Organizations (TIMOs) and Real Estate Investment Trusts (REITs). Since most timber REITs are publicly traded, management decisions are often based on their need to generate a consistent financial return from timber lands to meet shareholder expectations.

Privately held, family-owned timberland corporations are often organized as partnerships or limited liability corporations that focus on balancing long-term wealth, primarily through land appreciation and cash distributions to owners. Integrated forest products companies seek to maximize the long-term returns on their timberlands by minimizing harvest during periods of lower log prices and may purchase logs from outside suppliers to maintain short-term profitability for their processing operations.

Northwest Fiber Supply

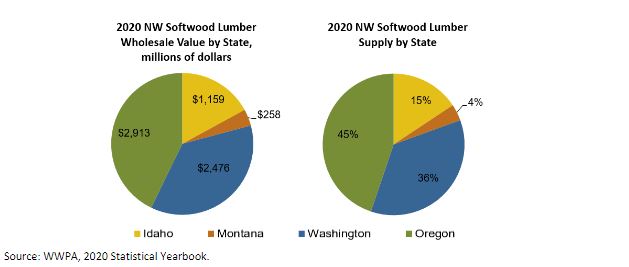

The Northwest and Southof theU.S.,and Canada are the largestforest products-producing regions. Washington, Oregon, Montana and Idaho account for just over 80%of the West’s1softwood lumber wholesale value and production. The four states’softwood lumber sales revenue was $6.8billion in 2020with production of 11.8billionboard feet.While production remained relatively unchanged from 2019, sales value surgedby 42% due to increased demand resulting from the COVID-19 pandemic.

Value Chain

Timberland

Northwest timberland consists almost entirely of softwood species including Douglas fir, western larch and hemlock. The other large softwood-producing regions in North America are the U.S. South, which grows Southern yellow pine, and western Canada, which grows similar species as the Northwest. Hardwoods are produced in deciduous forests, mostly concentrated in the Northeast and the Great Lakes states.

A timberland management plan is at the core of a timberland owner’s business plan. Understanding total timber inventory is the first step to a management plan. Foresters, typically contracted by the timberland owners, cruise timberlands to estimate merchantable volume and complete stocking surveys on younger stands. Data gathered includes species, height, diameter, age, defect, site quality, trees per acre and health of the forest. Cruising typically occurs when trees are 25 years old; top-tier timberland managers cruise stands every 10 years. After a cruise, inventory is estimated with mathematical equations in a forest inventory program. A statistical growth model is then used to calculate tree growth over time, which helps maintain an accurate understanding of timber inventory until the next cruise is completed.

Harvest Plans

A company’s harvest schedule is a critical part of a timberland management plan. Most large private and industrial timberland owners generally practice sustainable harvest management, meaning that within a given

period, harvest volume is equal to tree growth. When a timberland owner harvests above sustainable levels, new growth cannot keep pace with harvest, ultimately leading to a decline in timber inventory and total timberland valuations. Under a sustainable

growth model, annual harvest depends on the annual growth rate of timber.

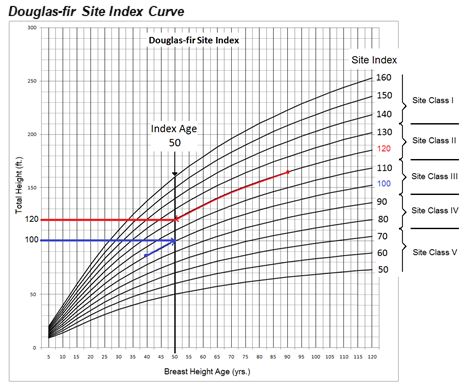

Site productivity is a major factor in determining sustainable yield. Trees grow at different rates depending on species, geography, climate and soil type. For

example, trees in northwest Oregon and southwest Washington grow quicker than trees in eastern Washington, northern Idaho and Montana due primarily to precipitation levels. Site-class indexes help identify how fast trees may grow in certain areas. The

site-class index is determined by a species’ total tree height at a base age of 50.

Harvest plans vary depending on management philosophy. Some timberland

owners complete a pre-commercial thin (PCT) and/or a commercial thin several years prior to the final harvest of a tract of land. A pre-commercial thin removes only small, pre-merchantable trees, leaving the cut trees in the stand. A commercial thin is

similar but occurs when the trees are larger and can be merchandised and sold into the market. While many Northwest timberland owners practice PCT on timberland tracts, commercial thinning is less common, and the decision is typically dependent on whether

the practice is profitable for a specific tract. The purpose of thinning is to free resources, such as soil nutrients and water, to maximize growth of the remaining trees. A company that employs commercial thinning will typically have a longer harvest

rotation, in some cases up to 60 years. At the other end of management philosophy, timberland owners who don’t thin tend to harvest trees at a much younger age, sometimes as young as 35 years, but typically 45 to 55 years in the Northwest. Ideally,

managers try to maximize economic value of the harvest. Therefore, harvest timing depends on growth rates and log prices.

Harvesting

On relatively flat terrain, ground-based equipment is used. On level to moderate slopes, trees are generally cut with either a feller buncher or a harvester. A feller buncher cuts a tree as it grabs and moves the tree to a pile. Multiple

trees can be bunched at one time before they are dropped into a pile. A harvester grabs, cuts, de-limbs and cuts the tree into predetermined log lengths.

If the terrain is too steep for equipment, trees may have to be manually cut

down with a chain saw or cabled equipment must be used. Cable yarding moves logs or whole, cut trees by suspension. A cable runs from a yarder at the top of the landing to an anchor at the bottom of the corridor. The technological advancement of tethered

logging is displacing yarder logging in some areas. With tethering, a piece of equipment is anchored at the top of a slope and a cable assists harvesting equipment, such as a feller buncher or harvester, down the steep slope. This method improves safety

and can be more cost effective versus traditional cable logging.

Once material reaches the landing, trees are de-limbed and cut to length, also known as bucked, if they weren’t cut initially in the brush and loaded onto trucks.

Some operators choose to merchandise logs in the forest for optimal transport to buyers. Logs are typically sold into two markets: domestic processing facilities or export log yards. In either case, logs are commonly divided into size and quality “sorts”

with higher quality (grade) logs receiving higher prices.

After harvest, the site is generally prepared for planting by spraying herbicides to control competing vegetation or mechanical methods to break-up the soil. Once a common

practice, broadcast burning is rarely used due to air quality and fire risk, but when applied is an effective site prep treatment. Trees are then planted at densities appropriate for the site to maximum future yield. A few years later, an aerial fertilizer

application may be beneficial and, depending on the management, the area may be thinned. Five to 10 years before harvest, another fertilizer application might be done, although it would be rare in the Northwest. Then final harvest is completed and the

cycle repeats.

Processors/Manufacturers

The term ‘sawmill’ can refer to stud or dimensional lumber mills – each specializes in processing a different size range of logs and produce different

end products. As owners continuously invest to keep their facilities competitive, the size and type of conversion equipment used in Northwest sawmills is continually evolving. Processors work to match their milling technology to the fiber resource available

to maximize profitability.

Major manufactured forest products include dimension and stud lumber; timbers; beams; panels such as plywood, sheathing or particleboard; engineered wood such as laminated veneer lumber (LVL); wood I-joists;

and glulam (glue-laminated) wood-beam products. Byproducts, primarily chips and sawdust, from log processing provide key resource inputs for the pulp and paper industry. Some manufacturers operate cogeneration plants that utilize wood chips to produce

electricity for the plant site and/or to sell back to the grid.

Mass Timber

The mass timber category comprises any large, solid-wood panels. It includes cross-laminated timber (CLT) and mass plywood panels (MPP), which are relatively new products for the industry. Some engineered wood products (EWP), such

as glulam, are also considered part of the mass timber product category. Mass timber is typically assembled with layers of cross laid dimensional lumber or plywood and is constructed in a variety of ways including with nails, dowels, glue, etc. The core

strength of mass timber makes it a viable construction material for larger multi-family or commercial buildings. Tests reveal that mass timber products are fire safe, and new developments improve safety during earthquakes.

A handful

of Northwest manufacturers are working on product innovation and certification of mass timber products. Although an exciting and growing development for the forest products industry, mass timber is currently a small portion of the industry as commercial

builders, engineers and architects have yet to widely adopt the product.

End Markets

From a consumption standpoint, manufacturing, residential improvements and single-family housing are the major end-users of softwood lumber. The health of the housing market heavily influences the forest products industry.

Drivers

Housing Starts

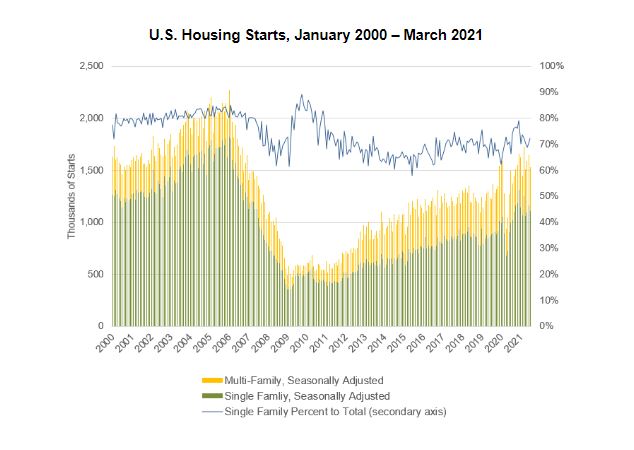

The Great Recession in 2008 enormously impacted the forest products industry. After peaking above an annualized seasonally adjusted rate of 2 million in 2005, housing starts fell to a low of 490,000 units in January 2009. Housing starts recovered slowly, withgrowth more lethargic than most predicted, largely attributed to considerable labor contraction in the home construction industry following the economic crisis. Post-recession, multi-family housing starts made up a larger percentage of total housing starts at the expense of single-family starts. This is less beneficial to the forest products industry since it typically takes 75%less lumber to build a multi-family unit than a single-family unit. In 2016, this trend started to reverse somewhat, with single-family units moving closer to 70%composition. In 2020 when COVID-19 forced everyone to stay at home, housing demand and the residential improvement sector boomed. Low interest rateslet built up demand loose and total housing starts finally reached pre-recession levelswith single family starts making up over 75% of total starts. While interest rates remain low, overall high prices fueled by demand and increased building costs have tapered off housing start growth in 2021.

North American Competitor Markets

Domestic

As noted, the U.S. South and Canada are other major wood-producing areas in North America. The South has experienced significant log price declines since 2006 primarily brought on by reduced demand due to manufacturing capacity

closures experienced during the Great Recession. Excess fiber supplies have kept log prices depressed, resulting in increased profitability among regional manufacturers during the last few years. High supply and good profitability have led increased

investments in manufacturing facility in the South.

Canada

Operating costs in North America vary by region and are the most expensive in Canada due to a declining fiber supply. The Northwest competes primarily on high value Douglas-fir (considered a superior wood for construction use) products, whereas the U.S. South utilizes cheap, abundant and good-quality Southern yellow pine.

Canada is a major softwood lumber producer and supplies approximately 20%-30% of the U.S. market (this accounts for about 50% of their total production). It also competes with the same export markets as the U.S. Canadian forestland is nearly all publicly owned, leased to private entities and managed under Forest Management Plans. While stumpage values and transportation rates are determined by the private market in the U.S., in Canada ,these are largely set (and many argue subsidized) by public entities. This has led to tensions among industry participants and while the Softwood Lumber Agreement (SLA) implemented in 2006 helped to ameliorate them, its expiration in 2015 has been followed by intense disputes and unsuccessful negotiations. Currently, the U.S. levies countervailing duties on Canadian lumber at 9%, though this is likely to increase to 18.3% come November 2021.

Policy and Regulation

Forest products producers face multiple federal and state policies and regulations affecting timberland management, harvesting activity, log access and manufacturing facility operations.

Endangered Species Act

The Endangered Species Act (ESA) classifies over 60% of the animals and plants (4,800 native species) in the U.S. as at risk. Impacts include closures of large public forest tracts to logging and limited logging on privately

owned forest tracts. Trade groups generally don’t support the ESA in its current form, proposing it should be rewritten to encourage improved habitats through sustainable management and habitat conservation.

The marbled murrelet,

a small Pacific seabird, is listed as threatened under the ESA. Several environmental groups are taking action to stop timberland harvest in an attempt to preserve habitat for the bird. However, according to Washington state’s Department of Natural

Resources, a long-term conservation strategy for marbled murrelets is not yet known.

Clean Water Act

The Clean Water Act (CWA) was passed in 1972 to restore and maintain the chemical, physical and biological integrity of U.S. waterways. In March 2012, the Environmental Protection Agency (EPA) released a memorandum that clarified the definition of ‘waters of the United States.’ However, due to a broad definition of a waterway, several groups oppose the regulation. In December 2018, the EPA and Department of the Army proposed a revised definition of a waterway, and on Feb. 14, 2019,theyproposed a new definition of “navigable waters.”On April 21, 2020, the EPA and the Department of the Army published the Navigable Waters Protection Rule, which defines “waters of the United States” (WOTUS) and navigable waters, perennial and intermittent tributaries that contribute surface water flow to such waters, certain lakes, ponds and impoundments of jurisdictional waters and wetlands adjacent to other jurisdictional waters. This became effective on June 22, 2020. Consequently, timberland owners must allocate additional resources to identify WOTUS tributaries and apply buffers during site prep and spring spray chemical applications.

Nonpoint source pollution is a more recent issue facing timberland owners. The regulation addresses skid trails possibly leading to erosion. This was a new issue within the last 10years, and many owners have adapted.

Road Maintenance and Abandonment Policy (RMAP)

Established in 2001, the RMAP’s purpose is to protect public resources such as water and fish in Washington state. Large landowners were required to submit a plan including how it would be implemented by July 1, 2016. The plan had to establish ways to improve fish passage, limit sediment and surface run-off, and minimize construction of new roads, among other things. Realizing the rule was costly to small woodland owners–those owning 80 acres or less with under 20 acres of contiguous land–the requirement for a plan was replaced with a checklist that includes all forest roads used for forest practice. While RMAP is set to end October 2021, the policies coming out of it will remain and continue to require landowners to maintain and bring roads up to forest practices standards.

Wildfire Fighting and Liability

Forest fires are an inherent risk for timberland owners, and the frequency and severity of them is increasing. Fire insurance on timberland is not generally considered to be a financially viable option, but private landowners use various methods to reduce the potential risk or impact of fire. Dispersed geographic ownership, membership in collective fire protection associations, investment in fire suppression equipment and assigning employees or other resources to participate in public firefighting efforts are commonly deployed tactics among timberland owners.

Aerial Application of Pesticide Ban

In 2017, voters in Lincoln County, Oregon, passed a measure to ban aerial pesticide applications. Landowners promptly filed a case against the ban arguing that Oregon state law preempts local governments from regulating pesticides. Supporters counter by claiming Oregon’s law to keep local governments from regulating pesticides is unconstitutional. The ban is currently in place and will remain in place unless the lawsuit, which is still in court, overturns the law. Grass root initiatives to further regulate and/or outright ban chemical applications isa constant battle across the west coast.

Appendix A

Best Practices

Forestland/Tree Farm Operations

Forestland operations are diverse in the Pacific Northwest, ranging from family and corporate ownerships going back generations, to relatively newer investment vehicles (e.g., TIMOs) that have acquired forestland in

the past 15 years. There have been two key, but differing, strategies for wealth management of tree farm operations. One group of tree farm operations creates wealth via consistent cash flows. These companies are valued primarily by cash flow available

for distribution and/or are managing their business to meet debt service requirements. These companies have maintained harvest levels slightly above or near sustainable levels even during the down cycle and augmented cash flow through sales of smaller,

non-strategic parcels. The second group of operations manages wealth by asset appreciation and harvesting lower amounts of timber in low log-price cycles and increasing harvest levels during stronger log-pricing periods. During the most recent down cycle

following the Great Recession, many operations curtailed harvest to levels below sustainable yields. As log prices rebounded, higher harvest levels capitalized on favorable pricing.

Opportunistic log sales (spot markets) and extended

delivery contracts are desired by tree farm operations. The following best-management practices allow operations to meet rapid, opportunistic log sales and maintain a consistent industry presence.

- Maintain adequate and accurate inventory data and systems to identify the tracts that meet highly desirable log species and size that fill immediate needs for mills.

- Build and maintain rocked roads that allow access to key tracts and accommodate transportation of logs during wet seasons.

- Maintain consistent relationships with contract logging operations, which improves access to loggers during periods of increased demand.

- Balance short-term needs of the processor with agreements to provide longer-term log supplies.

One of the most significant timberland owners in the Northwest are TIMOs that have aggressively acquired forestlands for more than a decade. The significant equity capital desiring investment in timberlands through these vehicles has influenced timberland

purchase prices and provided support to the value of this asset class. Most TIMOs have an investment horizon of a decade, but longer-term and evergreen (no firm end date) funds are becoming more popular. Overall, the timberland asset class remains a desirable

investment as a diversification strategy and hedge against inflation.

REITs are the other most significant timberland owners in the Northwest. REITs may or may not be a “pure play” timberland owner and can have exposure to downstream

manufacturing operations. REITs influence both the buying and selling side of the timberland ownership and tend to represent the larger of the publicly owned ownership structures trading on the exchanges. REITs generally were organized as other entities

(often C-corps) but have migrated to a REIT structure for tax advantage purposes. Key attributes of successful timberland owners include robust financial and inventory modeling analysis on timberland acquisitions, a broad customer base including some

contracted log supply agreements, strong relationships with logging contractors, strong inventory management and silviculture practices.

The timberland asset class is maturing as a significant proportion of the high-quality timberland estates

in the U.S. are already under industrial ownership. At the same time, new capital investment in timberland continues to increase, leading to growing international investments in timberland, as well as an expanding secondary market for timberland sales

between institutional investors. While this creates more liquidity in the timberland market, it also leads to more competition for investment opportunities and puts upward pressure on prices.

Processing Facilities

There are several major considerations for wood processing facilities, including fiber sourcing, inventory management, maintenance and capacity upgrades. While an organization’s leadership will take a long-term strategic approach to each, market conditions exert strong influences on decisions. Several examples include:

•Investing in new capacity to capitalize on increasing demand trends and low-cost fiber supply (currently a major trend in the U.S. South).

•Deferring maintenance to shore up financial positions and target capital improvements to improve productivity during economic downturns (occurred following the Great Recession).

•Building inventory in anticipation of a wildfire season (increasingly common as fire seasons get longer and more severe).

•Maintaining fiber supply agreements to ensure adequate supply (a common practice).

Processing facilities face constraints in which they have limited room to maneuver, including labor shortages and rising energy and feedstock costs (currently a major headwind). Key attributes of successful processors include active log procurement management (both in terms of delivered logs and contract stumpage agreements), continual analysis on maximum log procurement prices to maintain profitability, application of break-even analysis and project management expertise when completing in capital improvements.

Integrated Operations

One of the major benefits of integrated operations in the marketplace is the ability to rely on internal timber sources or look to the open market to cover supply needs. This control over throughput provides

more flexibility and increases a company’s ability to manage returns and profitability. During the downturn, many integrated operations sourced timber from the open market and allowed their fee-owned timber to continue growing in volume and value

on the stump. As supply tightened and timber prices began to rise, these operations resumed harvesting fee timber, at or slightly above sustainable yields to increase consolidated margins and meet growing customer needs. Integrated operations are heavily

focusing on capital improvements and processing efficiencies to reduce costs and increase grade yield and production. Key attributes of successful integrated operations include line of business reporting and analysis, market-based log transfer price mechanisms

and overall margin management in both sides of the business.

Strategic Opportunities

Primary strategic opportunities:

- Purchase of younger, pre-merchantable timber tracts as major industrial landowners act to optimize their timberland holdings (e.g., Weyerhaeuser).

- Capital investment in seedling genetics to improve harvest yields.

- Carbon sequestration projects to capitalize on the green/clean energy and climate movements.

- Partnerships with equity investments to pursue timberland acquisitions.

- Capital investments in mills to increase output or grade yield or to reduce costs (primarily log or labor).

- For processors (i.e. sawmills, plywood mills, etc.), expansion to the South where fiber supply is abundant and log costs are low, by comparison to the Northwest, and expected to remain low over the next 5-10 years.

Appendix B

Glossary

Aerial logging: Yarding system employing aerial lift, such as balloons or helicopters, of logs.

Afforestation: Establishment of forest crops by artificial methods, such as planting or sowing on land where trees have never grown.

Age: Mean age of the trees comprising a forest, crop or stand. In forests, the mean age of dominant (and sometimes co-dominant) trees is taken. The plantation age is generally taken from the year the plantation was begun, without adding the age of the nursery stock.

Age class: One of the intervals, commonly 5- or 10-year increments, into which the age range of tree crops is divided for classification or use.

Allowable cut: Volume of timber that may be harvested during a given period, usually equal to the forest’s net growth to maintain sustained production.

Allowable-cut effect: Allocation of anticipated future forest timber yields to the present allowable cut; this is employed to increase current harvest levels (especially when constrained by even flow) by spreading anticipated future growth over all the years in the rotation.

Annual allowable harvest: Quantity of timber scheduled to be removed from a particular management unit in one year.

Annual growth: The yearly increase in wood volume, usually expressed in terms of board feet, cords, cubic feet or tons per acre.

Area regulation: Method of controlling the annual or periodic acreage harvested from a forest, despite fluctuations in fiber-yield volumes. Leads to a managed forest.

Bare-root seedling: Tree seedling grown in a nursery bed. When large enough for transplanting, the seedling is lifted from the nursery bed and the dirt is removed from the roots before packaging.

Basal area: A measure of trees if cut at breast height, the area covered by the stumps. Trees per acre.

Bark beetle: An insect that bores into and beneath tree bark to lay its eggs. The feeding trails (galleries) girdle the tree and may kill it. Specific types of bark beetles attack different tree species. Most bark beetles can kill weakened trees.

Biomass: The total quantity (weight) of biological matter in a unit area, including all living organisms above and below ground, or the total quantity of one or more species in a unit area. Tree biomass components include wood, bark, foliage, roots, etc., of a single tree or of all the trees in a specified area.

Blow down: Trees felled by wind. Also known as windfall.

Blue-stain fungus: Most common form of fungal stain occurring in sapwood. Conifers are most susceptible but may also occur in light-colored heartwood of perishable timbers. Commonly develops in dead trees, logs, lumber and other wood products until the wood is dry. Reduces the grade of wood but does not significantly reduce the strength. Some blue-stain lumber is highly valued for specialty products.

Board foot: Unit of measurement for lumber and sawlogs. Refers to a 12-inch by 12-inch by 1-inch board or a segment of a log that will produce boards with these dimensions.

Bole: Tree stem that has roughly grown to a substantial thickness, capable of yielding sawtimber, veneer logs or large poles.

Bolt: A short log or a squared timber cut from a log (block), generally between 2-8 feet long.

Bone-dry ton (BDT): Wood pulp or residue that weighs 2,000 pounds at zero percent moisture content. Also known as an oven-dry ton.

Bone-dry unit: Wood residue that weighs 2,400 pounds at zero percent moisture content.

Break up: Period of time in the spring when melting snow creates soft soil conditions and high water in streams. Logging must usually be curtailed during this time.

Broadcast burn: Controlled fire used as a silvicultural treatment to burn a designated area within well-defined boundaries to reducing fuel hazards.

Buffer strip or buffer zone: Strip of uncut timber left between cutting units or adjacent to another resource. Also known as a green strip, leave strip or streamside management zone (SMZ). Also, strip of land varying in size and shape, preserving or enhancing aesthetic values around recreation sites and along roads, trails or water.

Bunch: To gather trees or logs into small piles for subsequent skidding by other equipment.

Butt: Base of a tree or log.

Butt rot: Decay or rot characteristically confined to the base or lower bole of a tree.

Cable: Wire rope used for lines in yarding systems.

Cable yarding: Taking logs from the stump area to a landing using an overhead system of winch-driven cables to which logs are attached with chokers. Also called skyline logging.

Cambium: Layer of living cells between the wood and the innermost bark of a tree.

Canopy: More or less continuous cover of branches and foliage formed collectively by adjacent tree crowns.

Cant: Log that is squared on two or more sides.

Carriage: Mechanical assembly that moves while suspended above the ground by the skyline. Logs are attached to the carriage or to the skidding line for yarding.

Catface: A wound on a tree or log usually caused by wildfire or by sideswiping with equipment.

Chain: A unit for measuring distance. A chain is 66 feet. An acre contains an area equal to 10 square chains. A section of land is 80-by-80 chains square, or 640 acres.

Chip: Small piece of wood used to make pulp, fuel or pressed board. Chips are made either from wood waste in a sawmill or pulpwood operation, or from pulpwood specifically cut for this purpose. Chips are larger and coarser than sawdust.

Chip-N-Saw® machine: Registered trade name for a machine that cuts logs into cants, by chipping off the round log sides without producing any sawdust. Cants are then sawn into lumber within the same machine center.

Choker: Short length of flexible wire, rope or chain used to attach logs to a winch line or directly to a tractor.

Clear-cut harvest: A harvest and regeneration technique removing all the trees in an area in one operation. Clear-cutting is commonly used with shade-intolerant species such as Douglas fir or lodgepole pine, which require full sunlight to reproduce and grow well. Clear-cutting produces an even-aged stand.

Clear-cutting: All merchantable trees on a setting to be yarded are felled.

Climax species: Plant species that will remain essentially unchanged in terms of species composition for as long as the site remains undisturbed.

Commercial thinning: Partial harvesting of a stand of trees for economic gains from the harvested trees and to accelerate the growth of the trees left standing.

Competition: Struggle among trees and other vegetation generally for limited nutrients, light and water present on a site. Competition can cause reduced tree growth. Severe competition in very dense stands may cause stand stagnation.

Conifer: Tree that is a gymnosperm, usually evergreen, with cones and needle-shaped or scalelike leaves, producing wood known commercially as softwood.

Continuous forest inventory: Timber sampling system that provides for periodic re-measurement of specific stands or plots of individual trees; this shows status and periodic change over time for the forest as a whole and its major subdivisions.

Coppice: In silviculture, a tree-cutting method in which renewal of a newly cutover area depends primarily on vegetative reproduction such as sprouting.

Coppice regeneration: Ability of certain hardwood species to regenerate by producing many new shoots from a cut stump.

Cord: A stack of wood that has a gross volume of 128 cubic feet. A standard cord measures 4 feet by 4 feet by 8 feet and should contain approximately 80 cubic feet of solid wood.

Core: Remaining wood after a veneer peeling operation is completed.

Corridor skidding: Logging procedure using cable yarders in which narrow clear-cuts are made through a stand. Cables are strung in these clear-cut corridors to transport logs from the woods to the landing. Between corridors only a portion of the trees in the stand are removed, and these harvested trees are skidded to the corridor.

Crop tree: A tree identified to be grown to maturity for the final harvest cut. Usually selected based on its species, its location relative to other trees and its quality.

Crown: Upper part of a tree, including the branches and foliage.

Crown class: A relative designation of tree crowns.

- Dominant trees are those with crowns above the general level of the canopy.

- Codominant trees are those with crowns forming the general level of the canopy.

- Intermediate trees are those with crowns below the general level of the canopy.

- Suppressed trees are those much shorter than the general level of the canopy.

Crown closure: In a young stand, the point when the crowns of the trees begin to touch each other.

Cruise: Survey of forest land that includes the location, volume, species, size and quality of timber stands.

Cull: A tree or log that is unmerchantable because of defects.

Cunit: Unit of volume of stacked pulpwood that equals 100 cubic feet of solid wood (does not include bark or air volume).

Debarker: Machine used to remove the bark from roundwood prior to processing into lumber, chips veneer or other wood products.

Deck: Pile of logs on a landing.

Defect: Crook, conk, decay, split, sweep or other injury that decreases the amount of usable wood that can be obtained from a log.

Diameter breast height (DBH): Measuring a tree’s diameter from breast height (about 5 feet)

Diameter inside bark: Diameter measurement of a standing tree or log in which the estimated or actual thickness of the bark is discounted.

Diameter limit: Maximum diameter of trees to be cut, as in a timber sales contract.

Diameter outside bark: Measurement of tree diameter in which the bark is included.

Directional felling: Predetermining the way a tree will land when it hits the ground. When shears are used, the wedge-shaped blade provides a lever that directs the tree into its lay.

Ecology: Study of plants and animals in relation to their physical and biological surroundings.

Ecosystem: Complex ecological community and environment forming a functional whole in nature.

Embedded grit: Grit (dirt, sap, oil, etc.) that is embedded in wood chips in the process of whole-tree chipping. This grit may be extremely difficult to remove when using chips in pulp and paper manufacture.

Epidemic: Widespread insect or disease incidence beyond normal proportions.

Even-aged management: Silvicultural system in which the individual trees originate at about the same time and are removed in one or more harvest cuts, after which a new stand is established.

Evenflow: Same amount of timber produced annually for an indefinite, extended period from a natural forest or other unit of land.

Feller buncher: A motorized harvester with an attachment that rapidly cuts and gathers several trees.

Firebreak: Any natural or constructed barrier used to segregate, stop and control the spread of fire or to provide a control line from which to work.

Forest floor: General term for the surface layer of soil supporting forest vegetation; includes all dead vegetation on the mineral soil surface in the forest, as well as litter and unincorporated humus.

Forest type: A group of tree species which, because of their environmental requirements, commonly grow together. Examples of forest types are the Douglas fir/hemlock type or the spruce/fir type. Also, a descriptive term used to group stands with similar composition and development characteristics.

Forwarder: A specialized vehicle that moves logs from the forest to the landing for loading onto logging trucks. Commonly used with cut-to-length harvesters.

Girdle: To encircle a tree with ax cuts or a saw kerf to sever the bark and cambium layer, thus killing the tree.

Grading: Evaluating and sorting trees, logs or lumber according to quality.

Gravity logging: Any cable system that depends on the force of gravity for downhill travel of the carriage.

Gross scale: Measurement of log volume in which no deduction is made for defect.

Grubbing: Removal of stumps from the ground by any of several methods or combination of methods.

Hardwood: A term describing broadleaf trees, usually deciduous, such as oak, maple, cottonwood, ash, alder and elm.

Head rig: Primary breakdown machine in a sawmill, used for the initial breakdown of logs by sawing along the grain. Logs are first cut into cants on the head rig before being sent on to other saws for further processing. Also known as head saw.

High grade: Good quality timber. Also, to cut the cream of the crop, taking only the best trees out of the stand.

Heartwood: The inner core of a woody stem, wholly composed of nonliving cells and usually differentiated from the outer enveloping layer (sapwood) by its darker color.

Hog fuel: Wood residue and waste product that is processed through a chipper or mill and produces coarse chips and clumps; can also include bark, sawdust, planer shavings, etc.

Intensive forest management: Use of a wide variety of silvicultural practices, such as planting, thinning, fertilization, harvesting and genetic improvement to increase the capability of the forest to produce fiber.

Interim forest: Forest that exists or will exist until conversion to a target forest is complete. An interim forest may develop under intensive forest management and may have excellent stocking, but it does not necessarily represent the forest desired at some future time. Also known as a transition forest.

Jammer: Lightweight, two-drum yarder usually on a truck with a spar and boom; may be used for both short-distance yarding and loading.

Jammer logging: Cable logging system generally restricted to one skidding line and used for winching logs up to 300 feet from the cutting area to a log collection point.

Kerf: Width of the cut made by a saw blade.

Leaders: Growing shoots or sprouts of a plant or tree.

Leave tree: Tree left standing after timber has been felled in a cutting unit.

Log rule: Table intended to show amounts of lumber that may be sawed from logs of different sizes under various assumed conditions.

Log scale: Measure of the volume of wood in a log or logs, usually expressed in board feet and based on various log scaling rules.

Long butt: Section cut from the bottom log of a tree and culled because of rot or other defect.

Long-line skidding: Cable system method of skidding logs to a landing from distances up to 1,200 feet. Also known as skyline skidding.

Long-span skidding: Cable system capable of skidding logs for 3,000 feet or more.

Main line: In cable yarding, the line used to bring logs to the landing. Also, on a skidder, the winch line.

Mature timber: Stand of trees that has attained an age or size that satisfies the primary economic goal for which it was managed.

MBF: Abbreviation for thousand board feet.

MMBF: Abbreviation for million board feet.

Mean annual increment: Total increment growth up to a given age divided by that age. Also, average growth per year.

Mechanized logging: Logging in which most or all of the hand labor is replaced by machines; requires a large outlay of capital.

Merchantable: Logs exceeding a minimum size and a minimum usable volume that are suitable for sale.

Metric ton: Unit of weight equal to 1,000 kilograms. Approximately 2,205 pounds.

Multiple entry: Entering a stand for commercial harvesting more than once in any one continuous rotation.

Multiple-use forestry: Concept of forest management that combines two or more objectives, such as production of wood or wood-derivative products, forage and browse for domestic livestock, proper environmental conditions for wildlife, landscape effects, protection against floods and erosion, recreation and protection of water supplies.

Natural regeneration: Renewal of the forest achieved either by natural seeding or from the vegetative reproduction of plants on the site.

Net annual growth: Increase in volume of trees during a specified year. Components of net annual growth include the increment of net volume of trees at the beginning of the specified year that survive to the year’s end, plus the net volume of trees reaching the minimum size class during the year, minus the volume of trees that died during the year, and minus the net volume of trees that become rough or rotten trees during the year.

Net scale: Actual amount of merchantable wood contained in a log as opposed to the gross scale, which includes defect.

Off-highway truck: Truck designed to handle loads exceeding legal highway size and weight restrictions. These trucks are not driven on highways; they are used in logging operations conducted on other types of roads.

Old growth: A forest ecosystem containing old trees, usually over 150 years old, and associated plants and wildlife characterized by diverse structure including gaps filled by shade-tolerant species.

Overmature: Point at which timber has begun to lessen in commercial value because of size, age, decay or other factors. Many trees in a virgin or old-growth stand are overmature and are, in fact, dying of old age.

Overrun: Difference between the log scale of a volume of logs and the volume of actual lumber produced from it.

Overstory: Layer of foliage in a forest canopy including the trees in a timber stand. Tall mature trees that rise above the shorter immature understory trees.

Overstory removal: Any silvicultural treatment with the desired result being the removal of the overstory component from the growing stock of a multistoried stand. Examples are outright harvest, girdling and simply felling the overstory.

Partial cut: Logging area in which only some of the trees are felled and bucked, as opposed to clear-cut.

Peeler: High grade log from which veneer is peeled, on a lathe, to produce plywood. Peelers are most frequently from higher quality trees. The resulting veneer is usually clear and used in sanded plywood.

Periodic annual increment: Mean annual growth or increase in volume during a specific period.

Pole: Young tree at least 4 inches and less than 12 inches in diameter breast height.

Plug seedling: A seedling tree grown in a small container, under carefully controlled environmental conditions, such as in a greenhouse. Seedlings are removed from containers for planting. Also called containerized seedling.

Pre-commercial thinning: Cutting trees from a young stand to reduce competition and improve growth potential of the remaining trees. Trees cut in a pre-commercial thinning have no commercial value and normally the felled trees are left in woods.

Pre-logging: Cutting specified high value wood products such as poles and pilings before cutting the remainder of the trees.

Prescribed burning: Deliberate use of fire under conditions where the area to be burned is predetermined and the intensity of the fire is controlled.

Pruning: Removal of live or dead branches from standing trees – usually the lower branches of young trees and of multiple leaders or shoots in plantation trees – for the improvement of the tree or its timber. Cutting away of superfluous growth, including roots, from any plant to improve its development.

Pulpwood: Logs cut primarily for the manufacture of paper, fiberboard or other wood fiber products. These logs are smaller than typical sawlogs processed for the manufacture of lumber or panel products. Dead trees often are cut for this purpose.

Punky: A soft, weak, often spongy condition in wood; caused by decay.

Reaction wood: Wood with distinctive anatomical and physical characteristics, formed typically in parts of leaning or crooked stems and in branches, that tends to restore the original position of the branch or stem if this has been disturbed. Also known as tension wood (in broadleaved trees) and compression wood (in conifers).

Reforestation: Reestablishing a forest on an area where forest vegetation has been removed.

Reload: To transfer logs from one mode of transportation to another or between vehicles.

Relog: To salvage small timber, culls and other residuals following the main logging operation.

Residuals: Also known as waste. Trees remaining after an intermediate or partial cutting of tree crops or stands. In general, residuals are byproducts of some operation. Examples are chips from lumber production and hog fuel from any wood processing operation.

Residual stand: Trees remaining in an area after the cutting operation has been completed.

Rigging: Cables, blocks and other equipment used in yarding logs.

Riparian: Pertaining to the area along the banks of a river, stream or lake.

Root rot: Disease that destroys tree roots, often killing the tree.

Rotation: Period of years between establishment of a stand of timber and the time when it is considered ready for final harvest and regeneration.

Rough cut: Lumber that has not been dressed (surfaced) but that has been sawn, edged and trimmed to at least show saw marks in the wood on the four longitudinal surfaces of each piece for its overall length.

Salvage logging: The harvest of timber that has been damaged by wind, fire, insect, ice or other environmental causes. A salvage logging operation is generally a small crew with lightweight equipment, that collects merchantable material too small or unsafe to be handled economically with big equipment.

Sapling: Young tree less than 4 inches in diameter breast height. The minimum diameter of saplings is usually, although not always, placed at 2 inches.

Sawlogs: Logs meeting minimum regional standards of diameter, length and defect. Logs must be at least 8 feet long, have a minimum diameter inside bark of usually 5+ inches, and not exceed maximum defect as specified by regional standards.

Scaling: Determination of the gross and net volume of logs using the customary commercial volumetric units for the product involved.

Scribner rule: Diagram log rule, one of the oldest in existence, that assumes 1-inch boards and a 1/4-inch kerf, makes a liberal allowance for slabs and disregards taper.

Second growth: Young forests that originated naturally or were planted on the site of a previous stand that was removed by cutting, fire or other cause.

Section: Land survey subdivision. Usually 1 square mile (640 acres).

Seedling: Young tree grown from seed, from the time of germination until it reaches sapling size. Also, in nursery practices, a young tree that has not been transplanted.

Seed tree: Tree that produces seeds; usually a superior tree left standing at the time of cutting to produce seeds for reforestation.

Select grade: High quality lumber. This grade is recommended for all finishing uses where fine appearance is essential. Widely used for high quality interior trim and cabinet work with natural, stain or enamel finishes.

Selective harvest: Uneven-aged silvicultural system in which single or small groups of trees are periodically selected to be removed from a large area so that age and size classes of the reproduction are mixed.

Self-loader: Logging truck with a loading device, generally a knuckle-boom loader, mounted behind the cab.

Setting: Temporary location of a cable yarding system, portable mill or other machine used for logging. Also, area yarded to one landing.

Shelterwood harvest: Method of harvesting timber so that selected trees remain scattered throughout the tract to provide seeds for regeneration and shelter for seedlings.

Side: Men and equipment needed to yard and load any one logging unit of an operation.

Silviculture: The art, science and practice of establishing, tending and reproducing forest stands with desired characteristics, based on knowledge of species characteristics and environmental requirements.

Site class: Classification based on ecological factors and the potential production capacity of an area; a measure of the relative production capacity of a site.

Site index: Measure of forest productivity generally expressed as the height in feet of dominant and codominant tree species at a specific index age such as 25, 50 or 100 years. Site indexes are normally grouped by site classes.

Site preparation: Preparing an area of land for forest establishment. Methods used may include clearing, chemical vegetation control or burning.

Skidding: Pulling logs from stump to the landing.

Skid trail: Skidder path through the woods.

Skyline carriage: The mechanism that moves back and forth along the cable system where all the chokers are attached. It is the device that makes pulling the logs on the cable possible.

Skyline: Cableway stretched tautly between two spar trees and used as a track for a skyline carriage.

Slash: Woody material or debris left on the ground after an area is logged.

Softwoods: Botanical grouping of trees that are usually evergreen and have needlelike or scale-like leaves. Also known as conifers and coniferous trees.

Sorting: Separation of forest products. Usually occurs at the landing.

Spar tree: Tree or mast on which rigging is hung for one of the many cable hauling systems.

Species: Group of similar individuals having many correlated characteristics and sharing a common gene pool. The species is the basic unit of taxonomy on which the binomial system has been established. The scientific name of a plant or animal gives the genus first and then the species as in Abies (genus) grandis (species). Species is both the singular and plural form of the word.

Stand: In silviculture and management, a tree community that possesses sufficient uniformity in composition, constitution, age, spatial arrangement or condition to be distinguishable from adjacent communities. This tree community forms a silvicultural or management entity, (for example, a sub-compartment). Both natural and artificial crops are included, and there is no connotation of a particular age. Also, in mensuration, the amount of timber and/or fuelwood standing on an area, generally expressed as volume per unit area, (for example, board feet per acre or cubic meters per hectare).

Stand density: Quantitative measure of tree stocking frequently expressed in terms of number of trees, basal area or volume per unit area.

Stand improvement: Measures such as thinning, release cutting, girdling, weeding or poisoning of unwanted trees to improve growing conditions.

Stocking: A description of the number of trees, basal area or volume per acre in a stand compared with a desirable level for best growth and management. Often stocking is used as a relative term, such as partially stocked, normally stocked or overstocked.

Stumpage: The monetary value of a tree or group of trees as they stand in the woods uncut (on the stump). Often this value is paid as a delivered log price less logging and transport costs.

Sustained yield: Timber yield that a forest can produce continuously at a given intensity of management. Sustained yield management therefore implies continuous production planned to achieve a balance between growth (increment) and harvest at the earliest practical time.

Sweep: Gradual bend in a standing tree or in a log, pole or piling.

Tailhold: In cable logging, the anchorage at the outer end of the skyline away from the landing. Also known as a tailhold.

Thinning: Cuttings made in immature stands to stimulate the growth of the trees that remain and to increase the total yield of useful material from the stand.

Timber: General term applied to forests and their products. Also, sawed lumber more than 4 inches by 4 inches in breadth and thickness.

Top: To cut off the unmerchantable top of a tree.

Tower: Steel mast used instead of a spar tree at the landing for cable yarding.

Trim allowance: Extra length allowed when bucking logs or estimating volume to account for loss from end injuries or uneven cuts.

Understory: That portion of the trees or other vegetation below the canopy in a forest stand.

Uneven-aged management: Silvicultural system in which individual trees originate at different times and result in a forest with trees of all ages and sizes. Harvest cuts are on an individual tree selection basis.

Viewshed: The landscape that can be seen from a particular viewpoint or along a transportation corridor.

Volume table: A table estimating the volume of wood in a standing tree based on its diameter and merchantable height.

Watershed: An area of land that collects and discharges water into a single stream or other outlet. Also called a catchment or drainage basin.

Widowmaker: Any limb, top, leaning tree or other material in the forest that is in danger of falling to the ground without warning, creating a safety hazard.

Windthrow: Trees blown over or knocked down by high wind, snow or ice.

Wolf tree: Large rough tree, generally not good for lumber.

Yard: Place where logs are accumulated.

Yarder: System of power-operated winches used to haul logs from a stump to a landing. Also known as a donkey.

Yarder wood: Wood brought into a yard in the form of tree lengths, logs or bolts, to be cut into shorter lengths.

Yarding: Moving logs by a cable system from stump to a landing.

Yield table: A table predicting volume, basal area or number of trees per acre to be found, or expected in the future, in fully stocked stands on specific sites at specified ages.

Y.U.M.: Yarding of unmerchantable material.

Stay up to date

Receive email notifications about Northwest and global and agricultural and economic perspectives, trends, programs, events, webinars and articles.

Subscribe